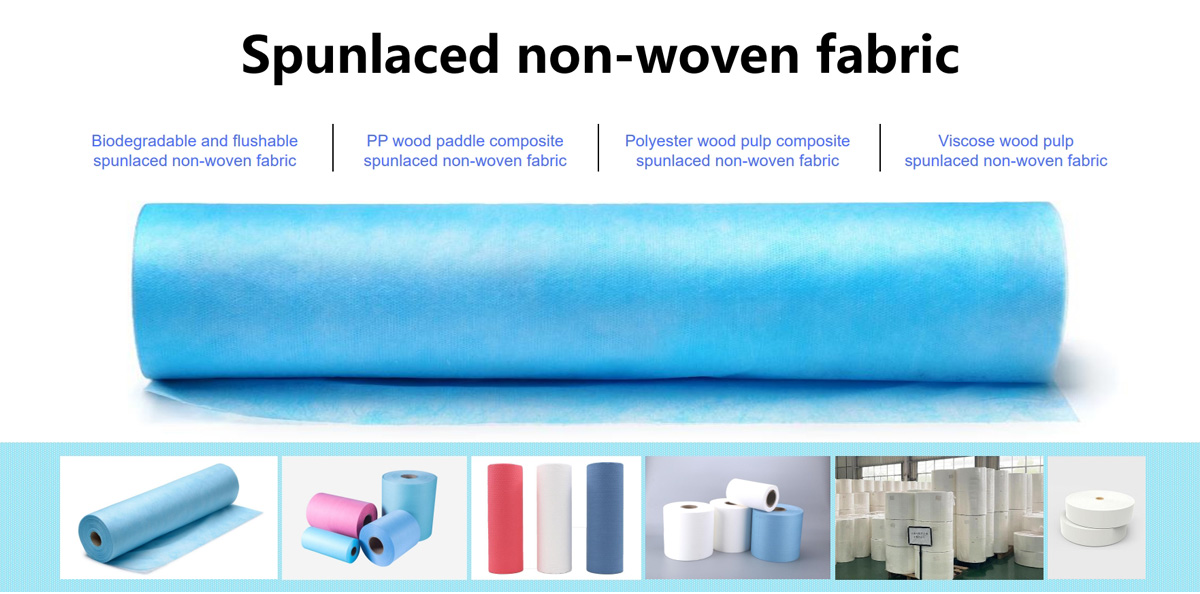

PLAIN POLYPROPYLENE PP WOOD PULP NONWOVEN Npuag

Kev piav qhia:

PP ntoo pulp non-woven npuag yog cov khoom siv tsis-woven muaj li ntawm polypropylene (PP) thiab ntoo pulp fiber. Nws muaj kev ua pa zoo heev, nqus dej thiab softness, nrog rau lub zog zoo thiab hnav tsis kam.

PP ntoo pulp non-woven fabrics feem ntau yog siv rau hauv kev kho mob thiab kev noj qab haus huv, cov khoom siv hauv tsev, cov khoom ntim thiab lwm yam.

Vim yog qhov sib ntxiv ntawm cov ntoo pulp fibers, PP ntoo pulp non-woven fabrics muaj kev ua tau zoo ib puag ncig, thiab kuj muaj kev xav zoo dua thiab kev nplij siab nrog lub zog tensile zoo thiab hnav tsis kam.

Feem ntau, PP ntoo pulp non-woven npuag yog cov khoom siv ntau yam nrog kev ua tau zoo thiab kev siv dav dav.

Cov yam ntxwv tseem ceeb:

1. Muab kev sib xyaw ua ke zoo heev ntawm lub zog thiab kev huv ntawm polypropylene nonwovens ua ke nrog cov khoom nqus dej ntawm cellulose.

2. Smooth kev ntxhib los mos thiab nqus dej zoo.

3. Tsawg tshaj plaws extractable qib thiab particle suav piv rau paj rwb.

4. Resistant mus rau cov kuab tshuaj thiab dilution, thiab chemically haum nrog dav siv tshuaj ntxuav thiab tshuaj tua kab mob.

5. Muaj peev xwm tiv taus autoclaving thaum tseem ua tus nqi tsim nyog thiab siv tau ntev.

Daim ntawv thov:

1. Kev tshem tawm cov dej ntws tawm dav dav thiab ntxuav qhov chaw

2. Kev sib xyaw ua ke thiab ntxhua khaub ncaws

3. Kev ntxuav ntawm khawb-rhiab qhov chaw

4. Kev so dav dav thiab tu hauv biotechnology ib puag ncig thiab kev npaj cov khoom

5. Tshem tawm cov etchants thiab lwm yam tshuaj lom

7. Lub tais hauv ob sab phlu thiab lwm yam kev sim siv

Haum rau:

1.ua cov khoom siv kho mob pov tseg,

2. Cov ntaub so ntswg huv,

3. cov ntaub ntub dej,

4. daim npog ntsej muag

5.cov ntaub ntawv ntim khoom, xws li cov hnab yuav khoom, lub hnab ntim khoom, thiab lwm yam.

Txheej txheem ntau lawm:

1. Raw khoom npaj: Sib tov polypropylene (PP) fiber ntau thiab ntoo pulp fiber nyob rau hauv ib tug tej yam kev faib ua feem, thiab ntxiv ib tug tsim nyog tus nqi ntawm additives, xws li ntxiv dag zog, lubricants, thiab lwm yam., rau pretreatment.

2. Kev sib xyaw thiab nplawm: Sib tov cov khoom siv fiber ntau pretreated nrog dej thiab do kom cov fibers tau tawg mus rau hauv dej kom tsim tau fiber ntau ncua.

3. Spunlace forming: Lub ncua kev kawm fiber ntau yog sprayed mus rau rotating mesh siv. Los ntawm qhov kev txiav txim ntawm kev kub siab dej ntws, cov fibers yog rearranged thiab interwoven ntawm lub mesh siv los ua ib tug ntub tsis-woven ntaub ntawm ib tug tej thickness.

4. Ua ntej ziab: Ua ntej ziab cov ntaub ntub dej uas tsis yog-woven kom tshem tawm ib feem ntawm cov dej noo thiab ua kom cov ntaub muaj zog.

5. Cov cua kub shaping: Cov cua kub yog siv los ua cov ntaub tsis-woven los ua cov ntaub ntawv ntawm cov fibers kom muaj zog thiab tshem tawm cov seem seem, kom cov ntaub tsis-woven tuaj yeem ua tau raws li qhov yuav tsum tau ua.

6. Coiling thiab ntim: Coil thiab ntim cov zoo li PP ntoo pulp spunlaced non-woven npuag rau kev thauj mus los tom ntej thiab siv.

Los ntawm cov txheej txheem saum toj no, spunlaced non-woven fabrics ntawm PP ntoo pulp tuaj yeem tsim tau, uas muaj tes zoo, nqus dej thiab lub zog, thiab tsim nyog rau ntau daim ntawv thov.

Tso koj cov lus:

-

Xiav Plain PP Woodpulp Spunlace Npuag nrog hig ...

-

Tuam Tshoj Hoobkas Nqe 60g Flushable Spunlace Tsis...

-

Biodegradable thiab Flushable Tsis Woven Fabric Ro ...

-

Yellow Polypropylene Woodpulp Nonwoven Npuag W ...

-

Pov tseg phuam Raw Khoom Spunlace Tsis Wove ...

-

30% Viscose / 70% Polyester Spunlace Nonwoven F ...